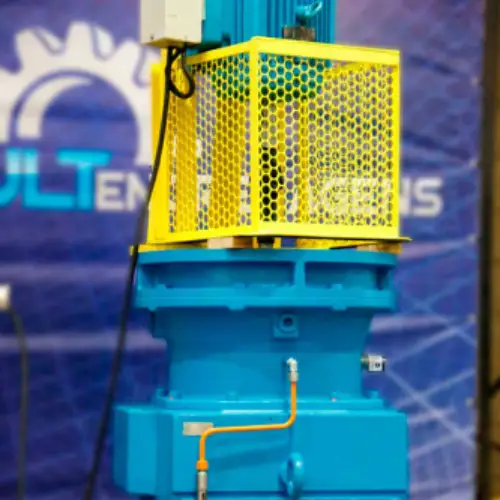

Cooling towers are used to remove heat and transfer residual heat to the atmosphere. The cooling mechanisms can involve water evaporation or air circulation to cool the working fluid. These towers are commonly used for water cooling in distilleries, sugar factories, oil refineries, chemical industries, power plants, and building refrigeration systems.

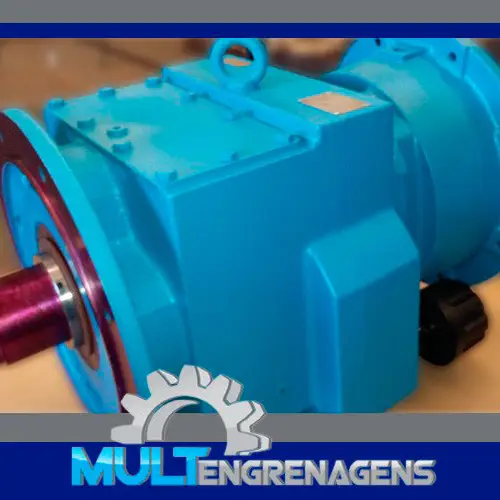

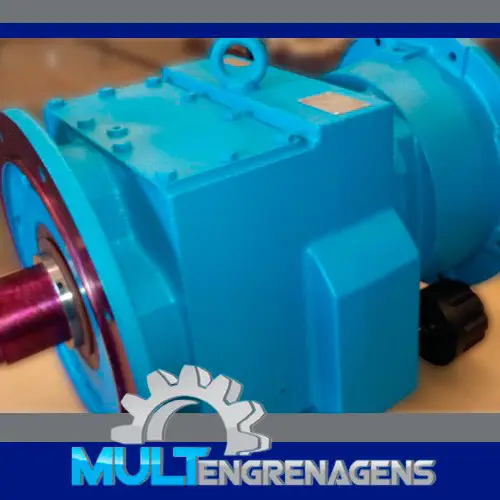

The ZK 168-K4 gearbox is essential for this process. Cooling towers vary in size, and due to the need to withstand high dynamic loads and inertia caused by the fan blades, a precise gearbox selection is required—where the ZK gearbox fits perfectly.

Among the key requirements is the perfect sealing of the housing, as the operating environment is extremely humid, along with reinforced output shaft bearings to withstand the high loads exerted by the fan blades. The ZK 168-K4 gearbox meets all these requirements.

The ZK 168-K4 gearbox absorbs axial and radial forces, ensuring reliable operation. It is designed for use in harsh environments where water is cooled and is also applied in heat exchange systems.

The ZK 168-K4 gearbox is specifically designed for cooling tower environments, featuring protective elements and an air filter against humidity. The unit is equipped with reinforced helical gears that enhance efficiency and productivity, ensuring smooth and quiet operation as the gear teeth gradually engage while rotating.

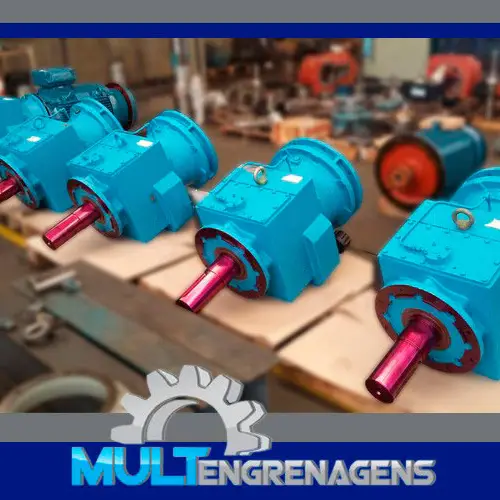

To achieve optimal cooling tower performance, the ZK 168-K4 gearbox must be integrated with multiple engineering principles, specialized materials, and advanced techniques to ensure proper equipment functionality. The system setup also includes coupling between the motor and gearbox, a silica gel breather, and upgraded gearing components within the ZK 168-K4 gearbox.o com a estrutura correta, inserindo também acoplamento entre motor e o redutor, respiro de sílica gel, e repotenciamento dos engrenamentos do redutor ZK 168-K4.

Mult Engrenagens has developed an exclusive design for the ZK 168-K4 gearbox, incorporating a mechanical lubrication pump that replaces traditional grease lubrication with oil lubrication for the input bearings, significantly extending the service life.

Mult Engrenagens, an ISO-certified company, serves various industrial sectors, including sugar and ethanol, pulp and paper, food processing, mining, steel, port operations, pharmaceuticals, rail transport, grain processing, wind energy, and oil industries. The company operates throughout Brazil and Latin America, specializing in the repair of gearboxes, speed increasers, and gears in general.