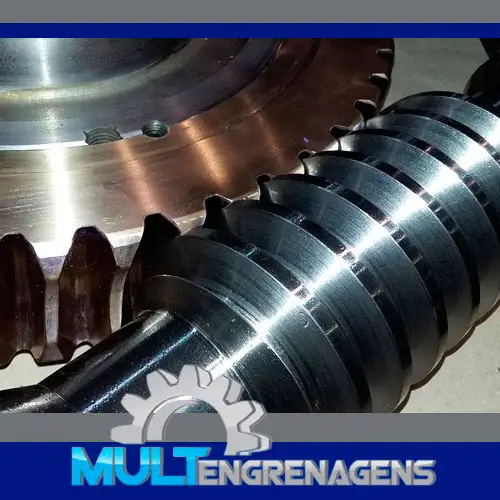

The crown gear manufacturing process involves the development of high-performance components that work in conjunction with worm shafts to transmit torque or reduce speed in industrial machinery. For this reason, the service must be carried out with precision and expertise to produce highly durable and resistant crown gears suitable for a wide range of equipment. Additionally, crown gear manufacturing should be entrusted to a market-recognized company specializing in the development of rotary assemblies and gearboxes. This ensures both the quality of the component and the advanced technology applied in its manufacturing process.

Beyond quality and technology in component development, a specialized crown gear manufacturing company must provide full support for installation and maintenance, including 24-hour technical assistance for its customers. Furthermore, the manufacturer should have a highly trained team with specific technical expertise in crown gear repairs when needed.

Another key responsibility of a crown gear manufacturing specialist is to offer flexible payment conditions, ensuring that the components deliver excellent cost-benefit ratios with accessible financing options and recognized market warranties. Additionally, a leading crown gear manufacturer provides:

Mult Engrenagens specializes in crown gear manufacturing, as well as other components for rotary shafts and gearboxes. The company is recognized for the high quality of its products and the use of cutting-edge technology in the development of industrial components.

In addition to manufacturing, Mult Engrenagens provides maintenance and technical support services, offering 24-hour assistance throughout Brazil and Latin America. This commitment to excellence has established the company as one of the industry’s most reputable and trusted providers.