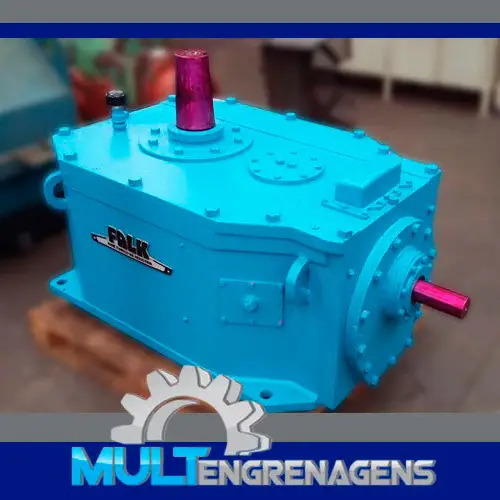

The Falk gearbox repair service aims to restore or enhance processes, performance, and durability. This service is highly sought after by industries across various sectors due to its excellent cost-benefit ratio.

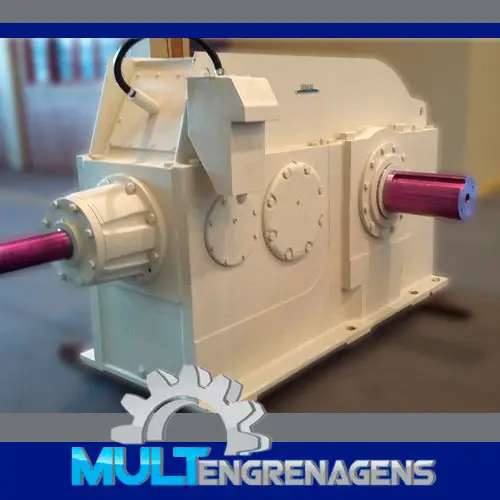

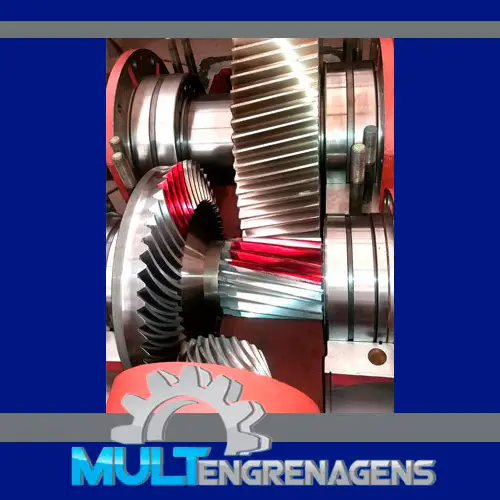

Like other gearbox models, the Falk gearbox consists of input and output shafts, gears, bearings, and housings, serving to reduce rotational speed. Falk gearbox repair is recommended for cases where the gearbox exhibits significant wear or requires component replacements such as pinions, pinion shafts, gears, bevel gear pairs, and hollow or solid shafts.

Falk gearbox repair is the best option, as the investment cost is significantly lower compared to purchasing a new unit. This service enhances performance and extends the lifespan of these gearboxes, which are known for their durability and the option of repowering.

Following Falk gearbox repair, the gearbox functions as if it were a new model, with the added advantage of a considerably lower investment compared to acquiring new equipment.

A specialized company is the best choice for Falk gearbox repair, ensuring that the service is performed correctly, adhering to current quality and safety standards. An experienced company in this field employs cutting-edge technology, has the necessary infrastructure, and provides a highly trained team to execute the service efficiently, making it the ideal solution.

For Falk gearbox repair to be conducted properly, meticulous planning is essential. The process requires high-quality machinery, tools, and materials, along with dedication, precision, and strict safety measures at every stage.

With the implementation of the NBR ISO 9001:2015 Quality Management System, Mult Engrenagens stands out in the national market for the quality it delivers in the manufacturing of industrial components and services. Backed by highly qualified professionals and a commitment to customer satisfaction, Mult Engrenagens has consistently provided technology and innovation with speed and competitive pricing to industries throughout Brazil.