To ensure equipment functionality and industrial productivity, it is essential to opt for gearbox repair when necessary. Proper inspection and repair are critical to extending the lifespan and optimizing the performance of machinery and equipment. Timely adjustments allow operations to resume their expected course, minimizing downtime and disruptions.

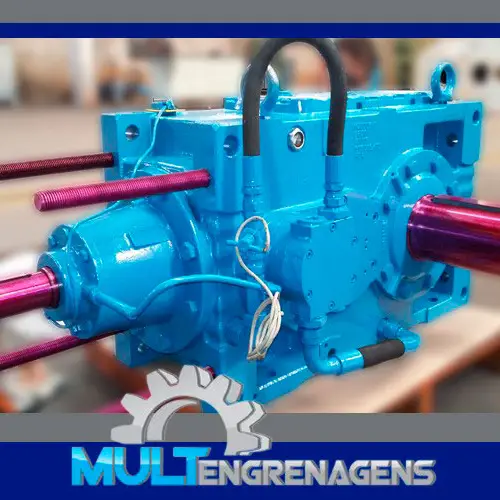

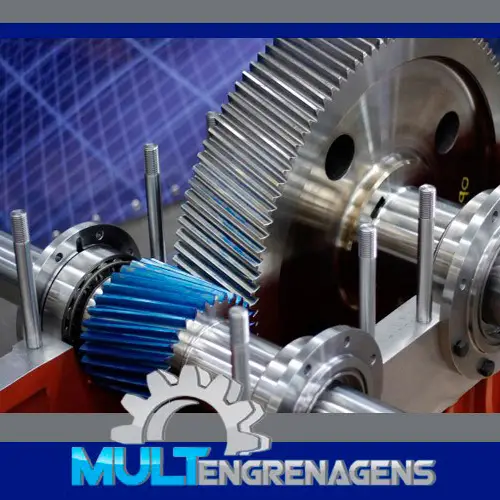

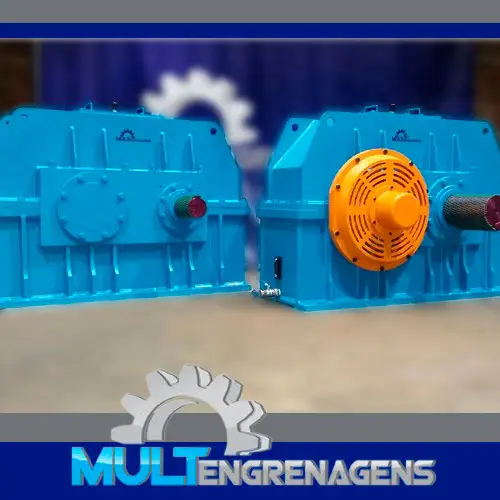

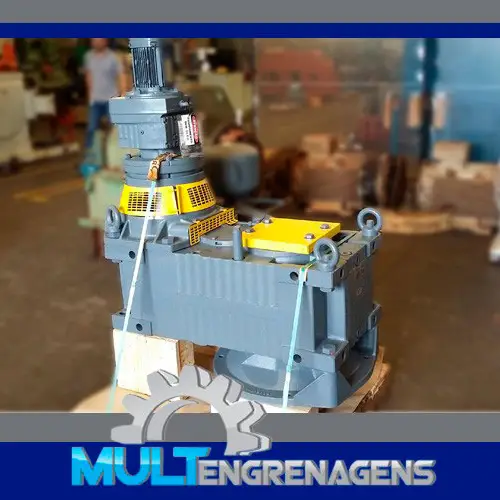

When a professional is engaged for repair, the process typically includes disassembly and inspection of the gearbox, thorough cleaning of internal components, dimensional and visual clearance checks, followed by reassembly. Gearbox repair can be performed on planetary, coaxial, angular, parallel shaft, and helical gearboxes, as well as speed variators, among others.

There are several types of gearbox maintenance, with the most common being preventive and corrective maintenance. Preventive maintenance, as the name suggests, helps avoid operational interruptions in industrial processes, preventing financial losses due to halted production. This approach also prevents performance degradation, which can lead to reduced productivity.

Through this type of maintenance, major failures are mitigated using tests, performance reports, and, when necessary, the replacement of parts as part of the gearbox repair process.

Corrective maintenance, on the other hand, is an indication that the gearbox is no longer performing efficiently. This process is used to restore the equipment and bring it back to full operational capacity. In more complex cases, replacing the damaged gearbox with a new unit may be necessary. In such situations, repair costs tend to be higher, and the required downtime is significantly longer compared to preventive maintenance.

The importance of gearbox repair directly impacts industrial productivity, regardless of the sector. A properly repaired gearbox ensures smooth machine operation, allowing production to continue without losses in productivity or financial setbacks for the industry.

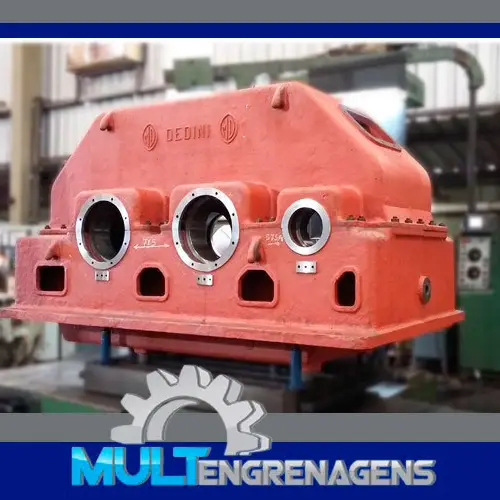

Mult Engrenagens provides gearbox repair and maintenance services through a highly qualified team that serves various industries, including sugar and ethanol, pulp and paper, mining, and others.

To efficiently meet both domestic and international market demands, the company invests in cutting-edge technology. Mult Engrenagens manufactures and repairs gearboxes to deliver fast and effective solutions for the industrial sector, servicing gearboxes from various brands, such as Falk, Flender, Cestari, Transmotecnica, SEW, Bonfiglioli, Sauer, Dedini, TGM, Sumitomo, Kumera, Hansen, and more.