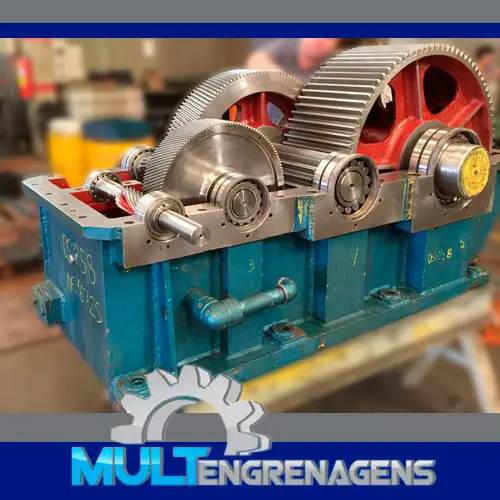

The parallel gear, also known as a spur gear, is one of the most common and widely used power transmission components. This gear is utilized in industrial machinery and equipment, as well as in gearboxes and vehicles of various sizes, including tractors and trucks. The defining characteristic of the parallel gear is its straight-cut teeth aligned parallel to the shaft, making it a rigid and efficient component. Due to its structural design, there is no need for positional adjustments during installation, simplifying the assembly process.

The parallel gear operates through direct contact between the teeth of two or more gears. Each tooth must engage precisely, ensuring optimal surface contact to prevent transmission system failures. Additionally, the rotational motion of the parallel gear is driven by a shaft, commonly referred to as a pinion shaft.

The parallel gear can be manufactured in various sizes and diameters, depending on application requirements and project specifications. This adaptability ensures efficient performance across different transmission systems.

One of the key advantages of the parallel gear is its high durability and resistance, allowing for an extended service life. However, regular preventive inspections are recommended to maintain optimal performance. Other notable benefits include:

Mult Engrenagens specializes in the manufacturing and development of power transmission components for industrial machinery, offering a comprehensive line of parallel gears. The company is recognized for its high-quality products, a team of highly qualified professionals, and flexible payment options, serving customers across Brazil and Latin America.

With years of experience in the industry, Mult Engrenagens also provides technical assistance and maintenance services, including 24-hour support. This solidifies its reputation as a market leader, demonstrating its commitment to reliability and excellence.