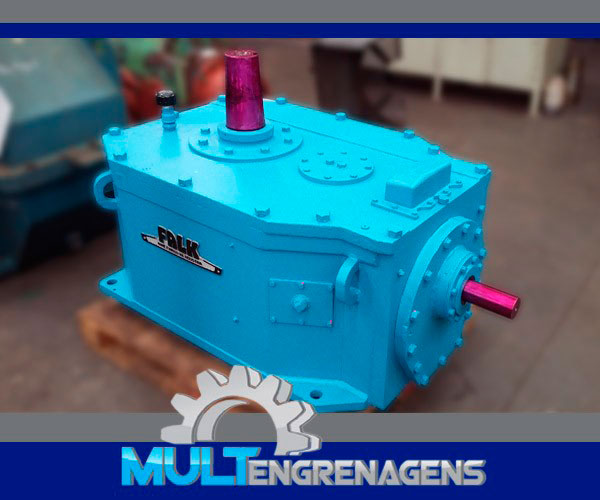

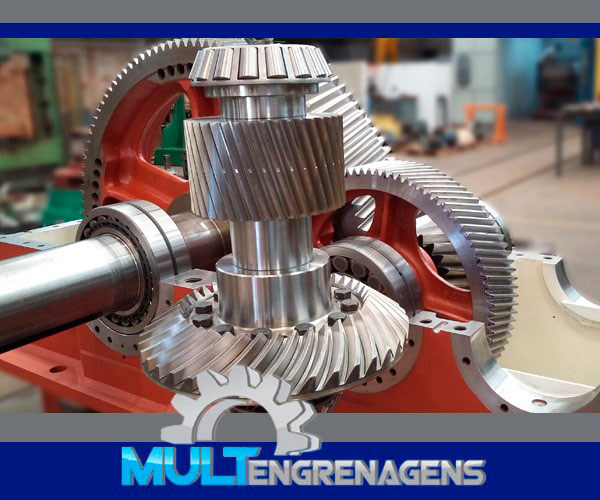

Useful for various applications, the orthogonal gearbox is responsible for reducing the speed of a drive system while increasing torque. Ideal for multiple industrial sectors, the orthogonal gearbox can be applied in agitators, conveyor systems, cement mills, and other operational scenarios.

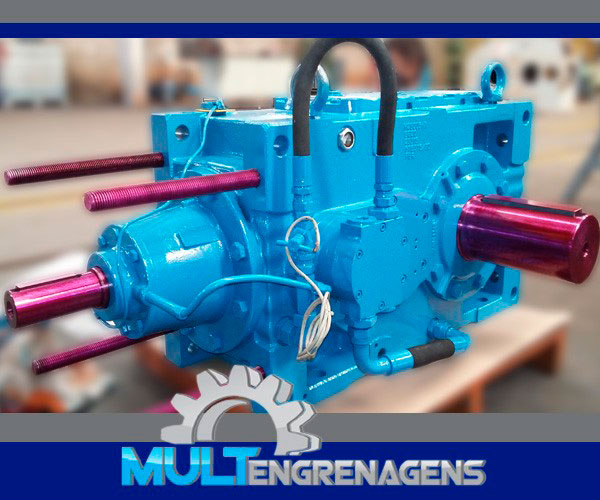

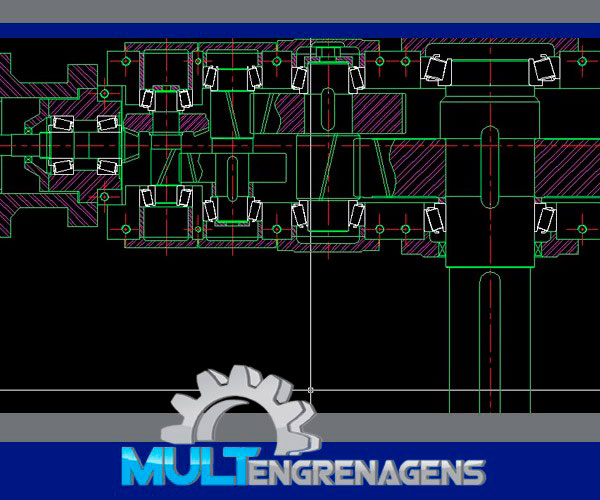

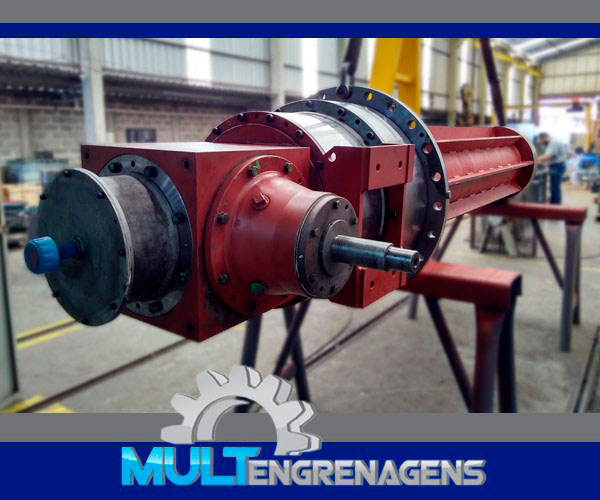

The orthogonal gearbox is manufactured and repaired to meet the diverse needs of applications that rely on its operation. Since these gearboxes handle varying loads, they require a robust, rigid, and highly resistant structure to prevent potential damage and risks associated with weight and friction.

An unexpected orthogonal gearbox failure could lead to a complete stoppage of an entire machine network. Therefore, it is essential that the gearbox offers mechanical reliability, resistance to heavy loads, and durability against external factors and human handling.

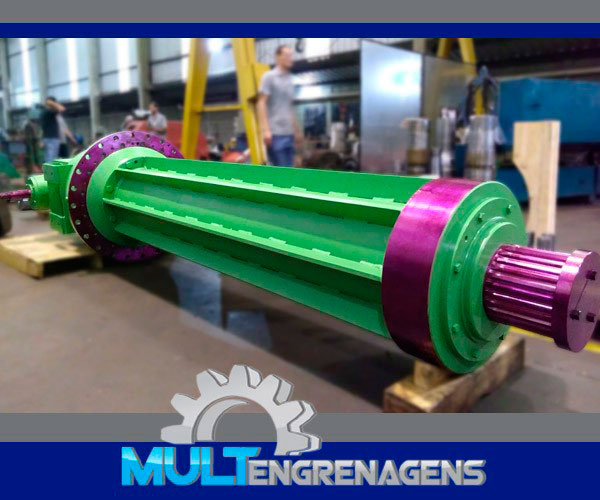

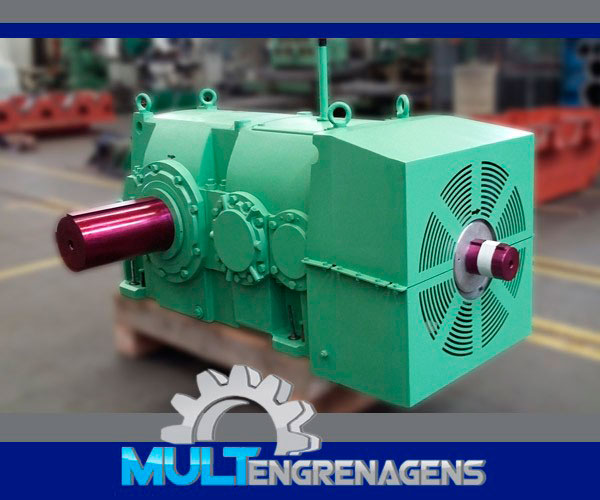

To accommodate a wide range of industrial applications, the orthogonal gearbox is produced in various sizes and dimensions. Additionally, it can be customized to meet the specific requirements of different industries. To ensure optimal performance, these gearboxes are equipped with precision-engineered motors designed for high efficiency and adaptability across different operational scales.

Investing in a high-quality orthogonal gearbox provides several advantages, including:

With a commitment to quality and reliability, Mult Engrenagens is recognized in the industry for manufacturing high-performance mechanical equipment with exceptional durability and efficiency. To enhance customer experience, Mult Engrenagens also provides a full range of specialized technical services, including installation, repair, and maintenance support.