The repair of a high-speed gearbox is a meticulous and precise process, as this mechanical device is primarily responsible for reducing the speed or rotation of a drive system. The high-speed gearbox is used when it is necessary to adjust a system with high rotation but low torque. In this scenario, the gearbox plays a crucial role by reducing speed and increasing torque.

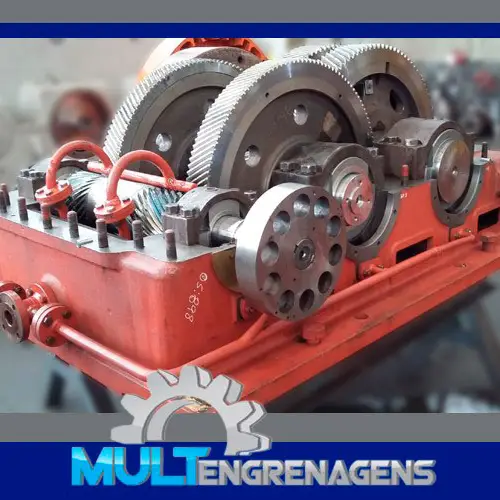

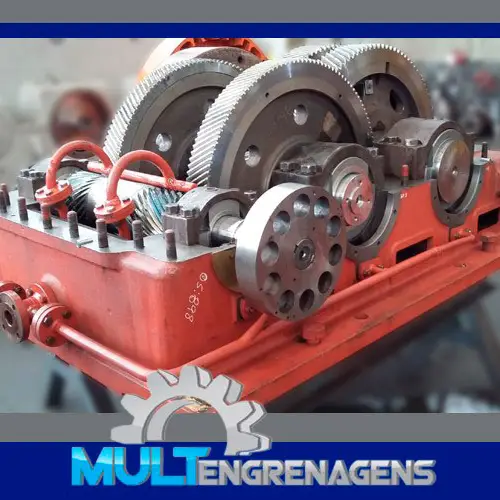

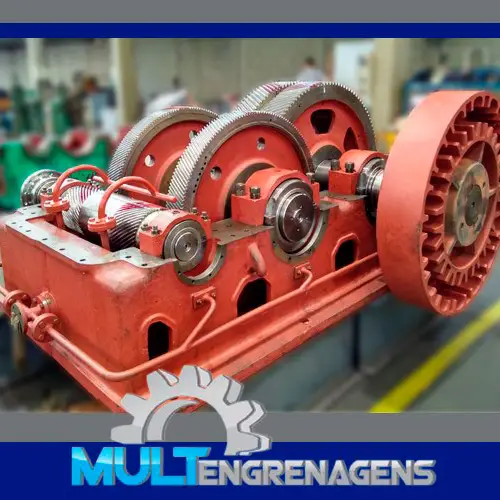

The basic composition of a high-speed gearbox typically includes input and output shafts, patent metal bearings, pinions, and helical or double-helical gears, all housed within a robust casing.

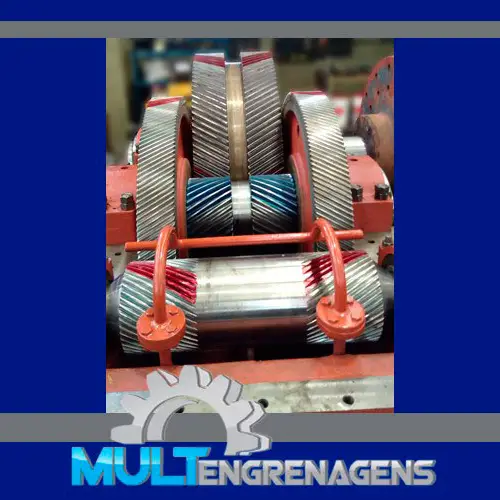

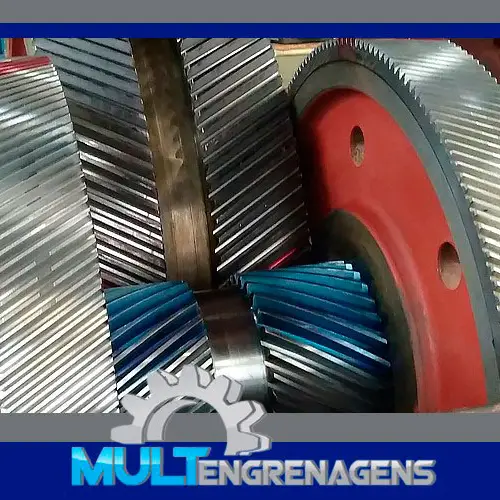

In industrial applications, high-speed gearboxes generally operate using a gear reduction system, often featuring double-helical gears. All high-speed gearboxes must have precise meshing to eliminate noise emissions, ensuring an extended service life and ease of maintenance.

For enhanced efficiency, double-helical gears are commonly used, as they provide more uniform power transmission, eliminate axial clearances, and offer superior dynamism and efficiency compared to straight-tooth gears.

Additionally, high-speed gearboxes with two stages are widely utilized in robust, high-speed systems requiring significant speed reductions. These gearboxes combine straight-tooth, helical, and double-helical gears, offering optimized performance for demanding applications.

Located in Sertãozinho, São Paulo, Mult Engrenagens is in the process of implementing the NBR ISO 9001:2015 Quality System. The company specializes in transmissions, gears, and speed reduction solutions, offering manufacturing, technical assistance, and services such as high-speed gearbox repair, gear refurbishment, special welding, and more.

Serving clients across Brazil and Latin America, Mult Engrenagens operates in key industries, including sugar and ethanol, pulp and paper, food processing, mining, steel, pharmaceuticals, railways, oil and gas, cement, and others. Today, the company is a leading reference in the sector.