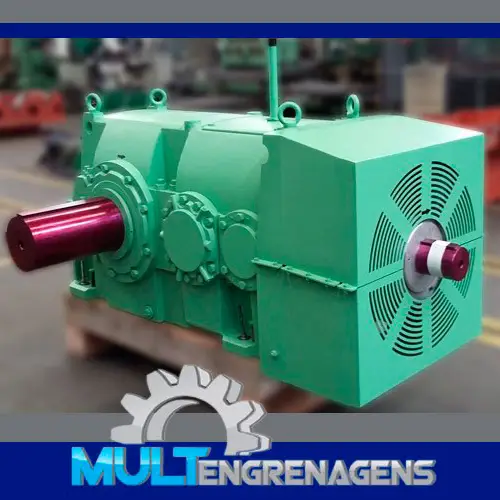

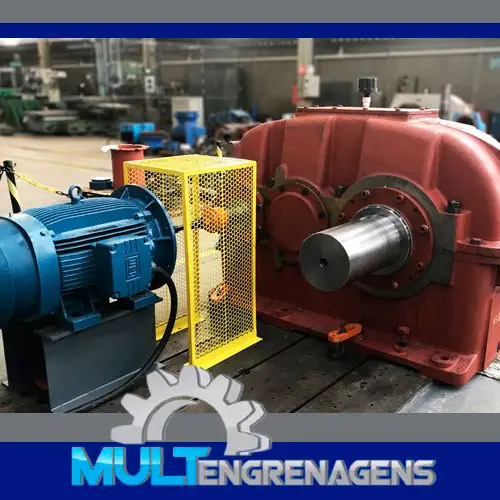

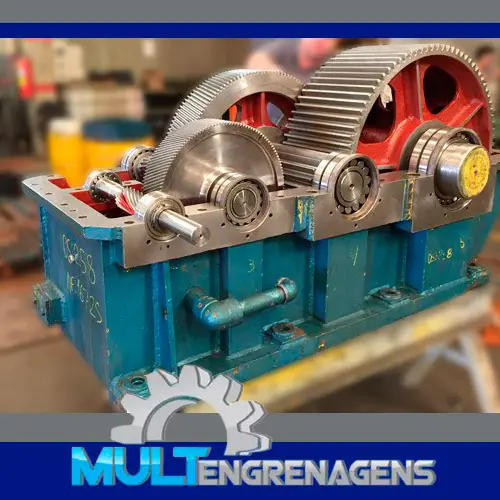

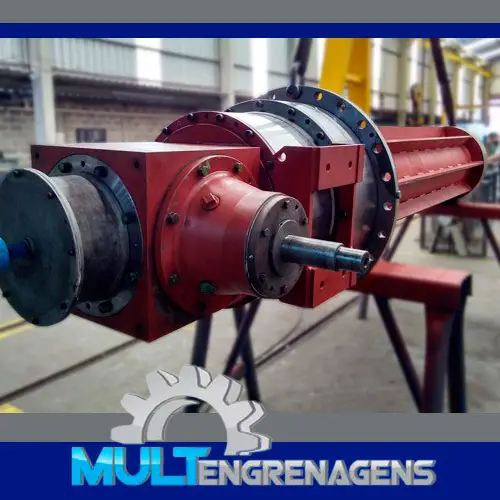

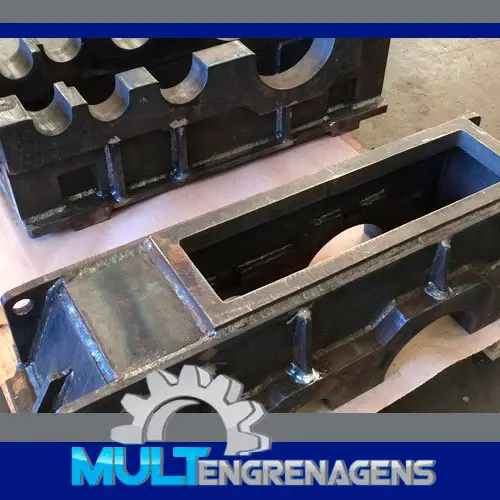

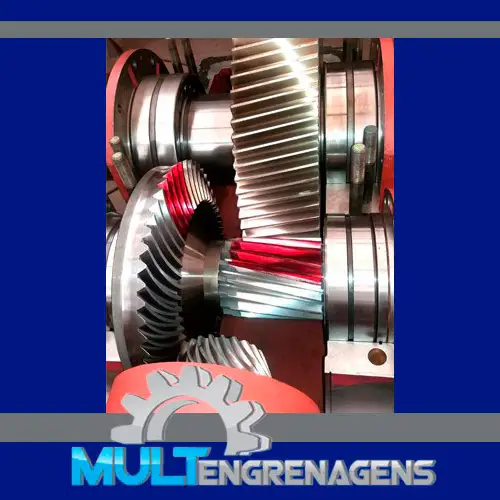

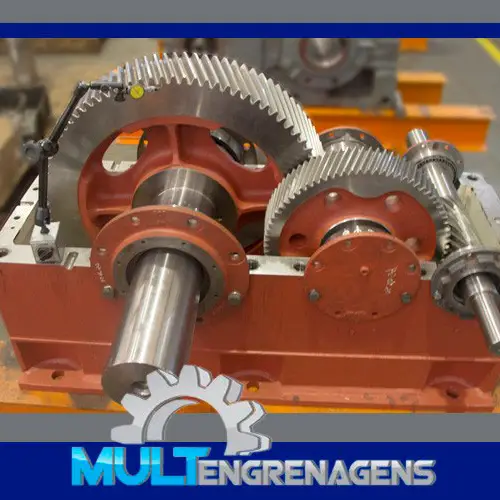

Gearboxes are designed to reduce rotational speed and increase the torque of drive systems. They are composed of shafts, bearings, gears, and housings.

Due to their critical role in equipment operation, gearbox repair must be carried out as soon as the first signs of inefficiency appear. The primary goal of repair is to restore functionality and optimize performance, preventing the need for a costly gearbox replacement.

Choosing gearbox repair ensures that production lines remain operational. Keeping machines running smoothly prevents downtime and financial losses caused by equipment failure.

The repair process can also contribute to gearbox repowering, improving the performance of components such as solar shafts, planetary gears, ring gears, and planet carriers. For instance, a Falk 2185 gearbox repair can be upgraded to a Falk 2187, with carburized and ground gearing following DIN 3962 standard, quality level five. This makes gearbox repair an excellent solution to extend equipment lifespan and increase capacity.

The primary objective of gearbox repair is to prevent equipment downtime and production disruptions. Predictive and preventive maintenance can mitigate future failures, making repairs a cost-effective alternative to purchasing a new gearbox.

A reliable and specialized company should be chosen for gearbox repair, ensuring that the following steps are completed:

After gearbox repair, it is recommended to inspect all external components that may affect performance, such as properly leveled and aligned mounting bases, coupling clearances, correct equipment installation, and precise machinery alignment and balancing. Additionally, predictive maintenance should be implemented to ensure long-term reliability and efficiency.

Mult Engrenagens is a leading company serving Brazil and Latin America, specializing in gearbox manufacturing, distribution, and repair services for various industrial brands. The company provides custom-built gearboxes and expert repair services for parallel, planetary, coaxial, and cycloidal gearboxes from brands such as Falk, Flender, Cestari, Transmotecnica, SEW, Bonfiglioli, Sauer, Dedini, TGM, Sumitomo, Kumera, Hansen, and many others.