The helical gear is a widely used component due to its versatility across various industries, including sugar-energy, mining, steel, citrus processing, chemical, cement, and metro-railway sectors. Its primary function is to transmit torque power, transferring motor speed to the gearbox and delivering torque to machines and equipment. As a critical mechanical element, the helical gear plays a fundamental role in the operation of industrial machinery.

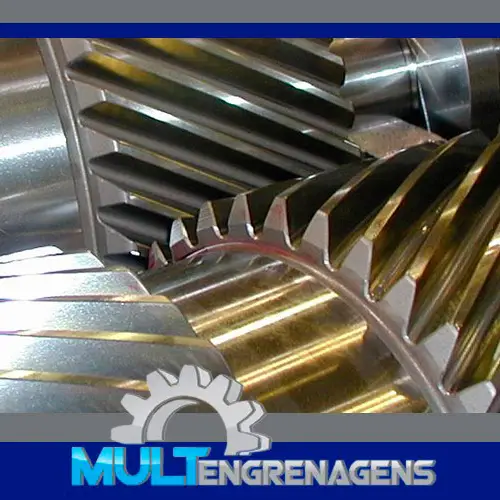

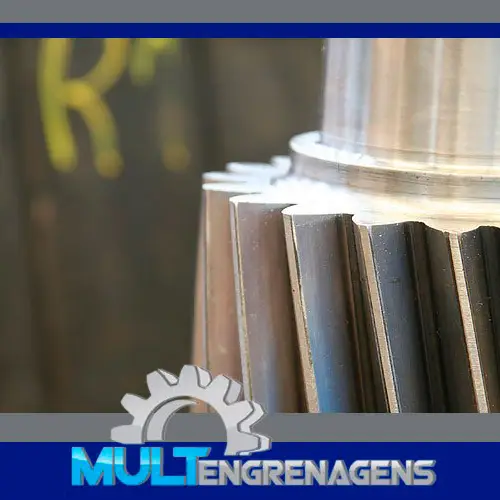

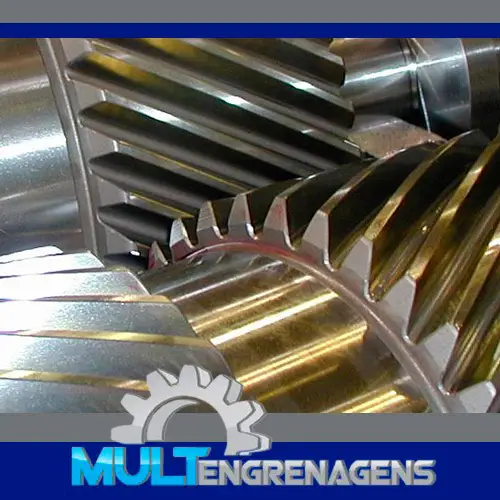

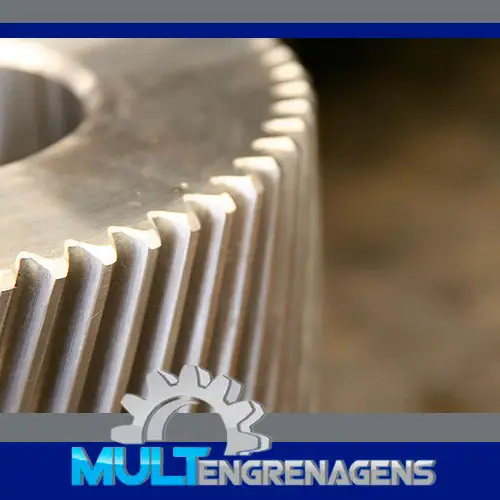

The helical gear gets its name from its helix-shaped teeth, which work together to facilitate smooth torque transmission. These gears operate in pairs, with the teeth of the pinion gear engaging with the helical gear throughout the process. This mechanism enables high-speed rotational force transmission, ensuring seamless integration within the machine's system.

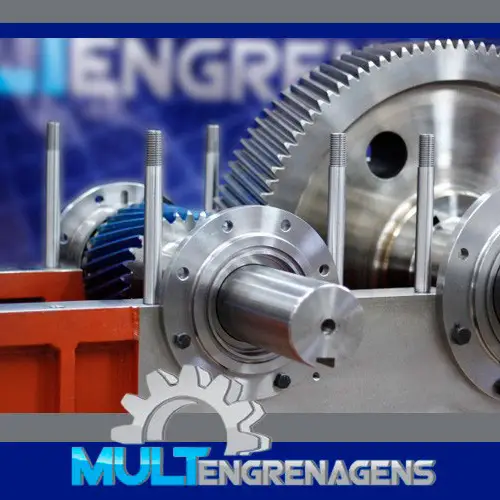

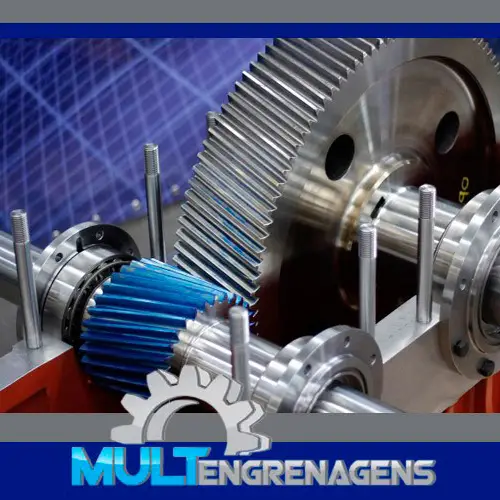

Due to its helical design, the helical gear is widely used in gearboxes with parallel shafts. It operates with minimal noise, even in heavy-duty machinery and high-speed applications. Additionally, helical gears feature a continuous rotation system, ensuring efficient power transmission from the motor.

One of the key advantages of helical gears is their ease of application and maintenance. They also offer an excellent cost-benefit ratio, making them a cost-effective investment for industrial operations. Other notable advantages include:

Mult Engrenagens specializes in developing high-performance rotary shafts for industrial applications, including helical gears. The company is recognized for its cutting-edge technology and high-quality manufacturing standards, meeting the strictest industry requirements.

Beyond gear manufacturing, Mult Engrenagens also provides repair services and technical support, solidifying its reputation as a leading industry reference. Operating across Brazil and Latin America, the company stands out for its commitment to excellence and reliability, offering the best solutions in the market.